Two years ago, I drew a flow chart to guide importers in case a final QC inspection was failed.

But the best is to detect problems during an in-process inspection (before the products are finished).

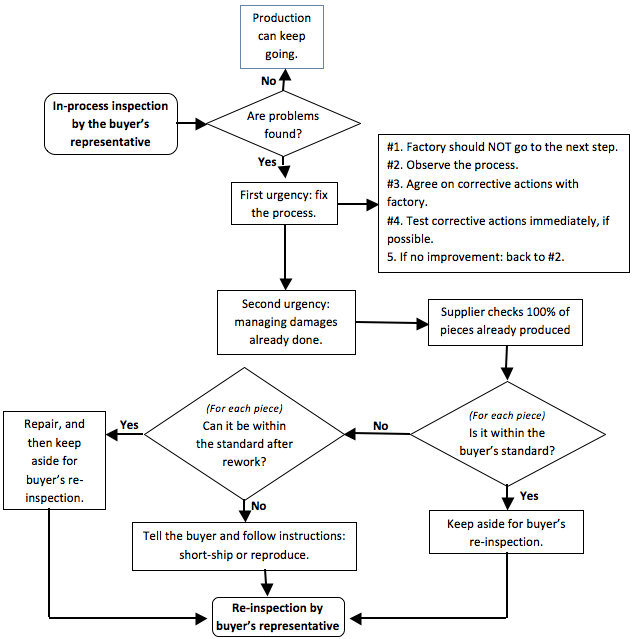

At this stage, if an issue is caught by an inspector, there are 2 objectives:

- To make sure the same problem won’t be present on the pieces that will go through that same process later;

- To make sure the pieces that already bear this problem are dealt with in the right way.

So I drew another flow chart, specifically for in-process inspections:

What do you think? Anything to add to this procedure?

No comments:

Post a Comment