During a product inspection, one of the main tasks is looking for defects on samples, categorizing them (critical/major/minor), and reporting them.

The maximum number of defects that is allowed is based on the AQL, which has to be set by the customer (or by an authority defined by the customer) prior to inspection.

Why? I see two reasons:

- It removes some subjectivity from the inspection process (subjectivity opens the door for corruption).

- It helps the suppliers understand the inspection process, and then replicate this process internally to increase chances of acceptance.

For the same reasons, it is always a good idea to give a list of defects before an inspection.

It is virtually impossible to list 100% of possible defects on a type of product (including its packaging). However, it is worth spending a few hours defining the most frequent defects.

It is virtually impossible to list 100% of possible defects on a type of product (including its packaging). However, it is worth spending a few hours defining the most frequent defects.

How to do? If you already have inspection reports in hand, look for the defects that come back most often. Specifically try to list the 20% of types of defects that represent 80% of the population of defects found. It is a good first step. After everybody is well aware of these “common” 20%, you will focus on 20% of the other defects that come back most often, etc. I am not inventing anything, this is actually a wide-spread tool for quality management.

And if you don’t have a history about past inspections of the same goods, I suggest you brainstorm about possible defects, or you can ask some people who have experience in this type of product.

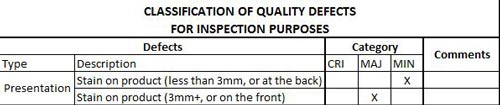

Once you have a list of defects, you should decide on each one’s category:

- Critical defects might harm a user, or do not respect the importing country’s regulations.

- Major defects are usually not accepted by end customer, so they would not buy the product.

- Minor defects are the slight issues that usually don’t prevent the sale of the product.

The resulting list might look something like this (with many more rows, hopefully):

No comments:

Post a Comment