We recently illustrated the importance of a detailed purchase order. It ensures a good understanding of the buyer’s requirements by the manufacturer and third party inspection company (or buyer’s QC). However the approval sample plays an important role too, especially during a product inspection in China.

Approval sample

An approval sample, also known as golden sample, is the result of the sample approval process. The sample approval process works as follows: the supplier sends the pre-production sample to the buyer. The buyer checks the sample and either approves or rejects it. When the sample is approved, the supplier starts producing the goods.

“Defining a Golden Sample is the go-ahead signal for production”

Note: the approval sample can be a production sample. However, depending on the product type, the buyer should rather approve the sample before the beginning of the production than after.

The role of approval samples during product inspections in China

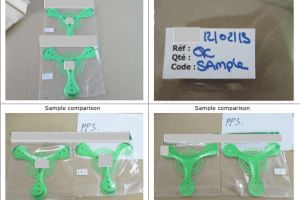

The approval sample is complementary to all the specifications already detailed in the purchase order. It allows inspectors to compare the quality of the finished goods to the approved golden sample. Let’s have a look at three specific examples:

- Color depends on fabric and texture. PMS color books are printed on cardboard. For other materials, it’s up to the inspector to decide whether a color is “the same” as the PMS color. The comparison is much easier when using a golden approval sample as it uses the same materials.

- Shape and feel are easier to verify by comparison than by looking at a picture or a technical drawing made by a graphic designer.

- Non-conformities can be classified as either acceptable or unacceptable (minor, major, critical defect). Buyers of lower-value products can use approval samples to specify which non-conformities are acceptable.

Without an approval sample, the QC can only base his judgment on the standard procedure. It means that all the non-conformities are defects. As a consequence they are listed and classified as critical, major or minor. The product inspection’s overall result will probably be “pending” or even “reject”. With an approval sample, the QC judgment is based on the standard procedure and the buyer’s approval sample. Non-conformities will always be mentioned in the report but may be classified as acceptable. When a buyer’s tolerance is relatively large, the inspection result may change into a “pass”.

When the approval sample is not “golden”

Approval samples can include defects. Buyers then ask their manufacturers to “fix this” or “change that color”. If that’s the case, make sure to inform the QC inspector about it. A good way is to take pictures of the approval sample and make comments in the picture.

And you: what kind of other role do you believe the approval sample plays during a product inspection in China?

No comments:

Post a Comment