Several of my clients are importers of lingerie. I advised some of them when they started buying from China and they needed an inspection firm. I noticed the same issue popped up for all of them: “we really need you to do fitting tests for the bras, or how can we be sure they are comfortable?”

The short answer is: try to rely on measurements rather than on fitting tests.

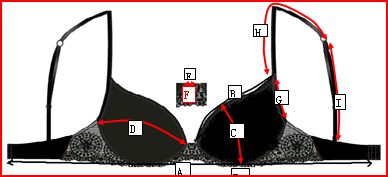

The most time-consuming part of lingerie inspections is taking the measurements and writing them down. But it is an essential part of the inspection job. And unfortunately I don’t think they can be replaced by fitting tests.

Why do many buyers prefer to rely on fitting tests?

It is technically possible that all measurements are acceptable but that the bra is not comfortable (or looks awful when worn).

But let’s be serious–it is seldom the case. And it can often be caught anyway by the inspector, if he checks whether the right kinds of fabrics are used and whether they were cut in the right direction. In that case, measuring the main points is enough.

Why do I think fitting tests should be avoided to confirm acceptance of the products?

It is simply too subjective. Buyers should tell the factory what is expected of them in clear terms–for example “bulk products should be within tolerances regarding measurements, according to this size chart”.

If a factory respects the size charts but the purchaser or the modelist rejects the goods because “we did some tests and they don’t fit correctly”, how can they understand (and accept) it?

So, how should an importer of lingerie proceed?

They should be very careful when approving size samples, and then check again the pre-production samples (which are made with the same fabrics and accessories as bulk production). These samples should fit nicely and should be within tolerances–if not, size charts should be revised accordingly.

Then, inspections of production should only rely on the size charts accepted by the factory and by the buyer. There are two possible situations:

1. If the vast majority of samples are within tolerances, measurements are accepted. No fitting test is necessary.

2. If too many samples are outside a tolerance, measurements are refused. Here again, there can be two cases:

2. 1. If the buyer is fairly certain of the impact on fitting (i.e. either no impact or a strong impact), a decision (ship vs. sort out and repair) can be taken right away.

2. 2. If the effect on comfort is not obvious, the importer can take a decision after some fitting tests (on samples previously picked up by the inspector).

No comments:

Post a Comment