The inspection during production (or “DUPRO”) is the second most frequent type of QC inspection, after the final random inspection (see the list of the major types of quality inspection services).

Why is it often necessary?

Inspecting the goods after production is finished is often too late. In some cases, a whole order is found unsellable just before shipment; the factory is unable to repair it; re-ordering materials and re-producing would take 2 months; and the supplier refuses to do it for free.

After a few such experiences, many importers conclude that inspection should take place earlier (during production).

The objective is to catch quality issues before it is too late:

- The few products that were already manufactured can (hopefully) be re-worked without inducing a delay;

- The same issues can be avoided on the rest of production.

If quality problems are found at this stage, buyers are advised to force the supplier to work on a corrective action plan. It is a way to document an issue to make sure it is repaired appropriately… and also avoided for repeat orders.

A side about communication with suppliers… It is often better to frame it this way:

An inspector will come to check a few samples to help you adjust your internal QC efforts, so that both of us have no last-minute surprise.”

When to conduct an inspection during production?

The ideal timing actually depends on the product type and the experience of the factory. But a few rules of thumb can be followed for 80% of consumer goods, if these conditions are true:

- The factory is used to making this kind of product involving this level of complexity,

- The cycle time to get the first finished products out of the lines is no more than 10 days.

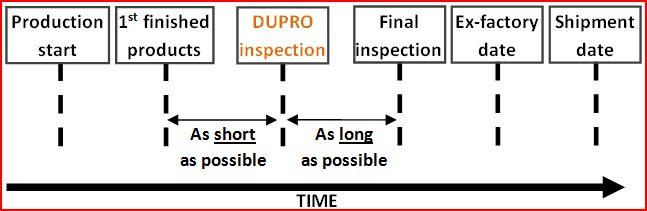

In such cases, the below sketch is applicable:

Let’s take the example of an order of 20,000 pieces that takes 30 days to manufacture. If some finished products appear 8 days after production started, and if 600 products are available for inspection 4 days later (in the early morning), the good time for a DUPRO is 12 days after production start.

There are two dangers to avoid:

Checking too early

The very first products that get off the lines are not representative of average quality (they are usually worse). And the factory needs to have time for their internal QC, or they will claim that “of course, they would not ship this kind of defects.”

And if you think you can inspect products that have gone through a few processes but are not finished, you’d better be sure you can find quality issues this way. It depends on the type of products, but inspection firms usually don’t have the expertise to do that.

Checking too late

Most factories in Asia produce in very large batches–this is why finished products often do not appear before one or two weeks into production (and sometimes more).

If the buyer waits until 50% of the products are finished, it is likely that another 30% are already being processed. If quality issues are found at that stage, they might already be present on 80% of the order!

What is checked during production?

Naturally, the inspector verifies that production is taking place in the workshop. He can also ask for the updated production planning.

An inspection during production can be failed for three reasons:

1. Non-conformity to specs:

All the relevant aspects of the product (quantity, components, assembly, aesthetics, function, size, labeling…) are controlled, based on the buyer’s requirements.

2. Too many visual defects:

Based on the sampling plan, the inspector selects and checks some products, and then he compares the number of defects to the AQL limits.

3. Failed on-site test(s):

Some simple tests can be done by the inspector in the factory (instead of sending samples to a laboratory). For example: a full function check, to make sure that a DVD player really “works”.

What are the limits of an inspection during production?

First, it is not enough in itself. A factory might identify some problems, hide them away from the inspector, and then ship them out. This is why an inspection during production should be followed by a final random inspection, to confirm average quality.

Second, for sensitive projects, the factory might need some guidance from the beginning of production. This is the work of a technician capable of setting up processes as required.

One of my clients was sending some experienced sewing technicians to China: they were checking the way the fabric was cut, and then the way the operators did they job. Unfortunately, they stopped doing it because Chinese factories did not welcome their “assistance” and did not apply their “suggestions”… It can only work with small workshops that have few other customers.

Third, in certain cases production takes place on multiple lines or even in multiple factories. One inspector will not be able to get an idea of average quality in one day… He should stay for longer and monitor both production schedule and quality.

Fourth, very often labeling and packing cannot be checked properly. Chinese factories tend to receive packing accessories towards the end of production (because they delay payments of inputs as much as they can).

No comments:

Post a Comment