If you import from China, you are probably frustrated by the lack of updates about production advancement. Not only that, but you must have been shocked by the lack of reliability of any update or forecast that your suppliers give you.

Simple reporting from the supplier

For those of you who purchase from a trading company, or who have a very good relationship with a factory, you should request at least a weekly update about each of your running orders.

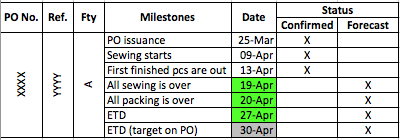

It can take the shape of the below table, for example. The most important is to keep this reporting really, really simple.

With a bit of color coding, you will be able to see immediately most upcoming delays. In the above example, all seems to be running all right (green color).

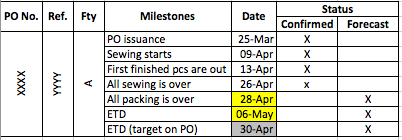

Let’s say the factory notices some quality issues and needs to rework some of the goods. The “all sewing is over” milestone might be delayed, and the table might look like this:

Then, naturally, you should audit this update process by checking the status of production. Either you or an inspector can do it easily, and check product quality at the same time.

A few words of caution about the request for updates (from a comment written on a past article):

The attitude (on both sides) and the way we check and request updates is really important. I have seen many requests for update sent to suppliers by email that are just a one liner and lead to either a one liner ping pong game or a flaming chain of email. Not the way to project manage a p.o.

More in-depth planning

For those of you who ABSOLUTELY MUST FOLLOW VERY VERY CLOSELY a particularly sensitive order, there are basically 2 solutions:

- Come in China for several weeks.

- Pay a third-party quality assurance firm for stationing an inspector in the factory every day.

Either way, you should work more professionally. You should take a project managementapproach. The “Gantt chart” is a useful tool, if you have the resources to work out the planning and keep it updated. Read this article to understand how to use it.

The main problem is that it is very time-consuming to prepare. More than 99% of factories will be unwilling or unable to keep such a document updated by themselves. It is only viable when it makes sense economically to station someone in the factory over several weeks.

Has anybody got other suggestions?

No comments:

Post a Comment