Inexperienced importers usually ask the same questions, one of which is: when should we inspect the quality of our products?

There are mainly two types of inspections:

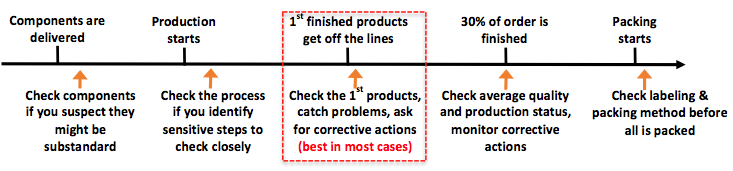

Inspection during production: very useful to catch problems early, when corrective actions can still be implemented and schedules can be updated. It should target the main risks identified by the buyer:

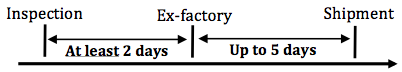

Final inspection (after packing): the bare minimum for most productions. The only time an inspector can pick up samples totally at random. The timing is virtually always the same:

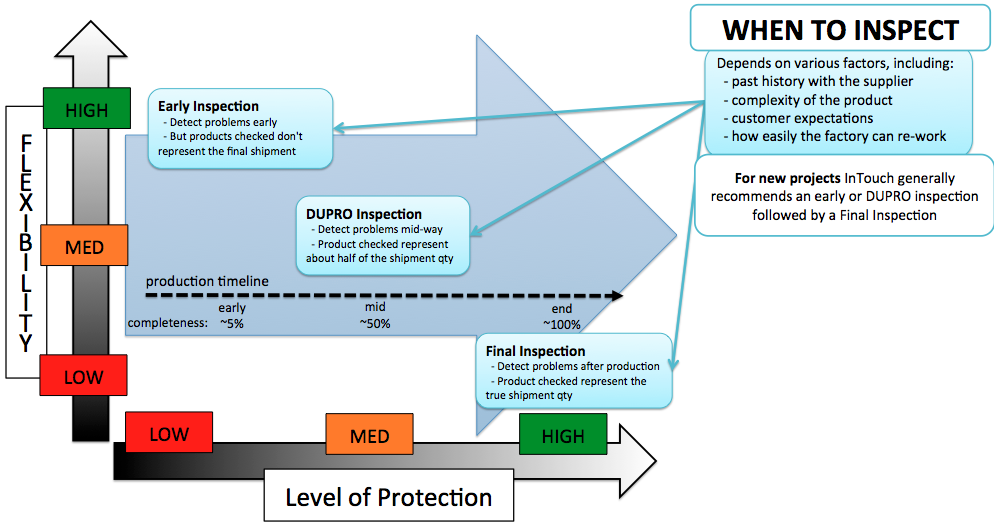

My friend Andrew Reich from InTouch just published a useful infographic that captures all these nuances (click on the image to enlarge it):

Is something missing? What do you think?

No comments:

Post a Comment