In good factories, the leaders look at the future and wonder how to make their company stronger. They usually have an action plan that will support process improvement. That’s how they will improve their quality, cut lead times, and contain costs.

When I go to Chinese factories, managers very seldom tell me “here is our action plan”. They seem to respond to every day’s urgencies:

- A supplier is late in delivering some materials, and the customer will ask us to send the goods by air? Let’s call the supplier, or go and see them, right away.

- A key supervisor just quit? Let’s figure out how to keep his department going for the day.

- A batch was rejected for poor quality? Let’s look at the the issues and decide what to do.

Do they really have no plan for improvements?

Actually, they often do. The boss will have a few priorities in mind — most of them on how to get new customers, and a few about their operations.

There are generally 2 issues with these plans:

- Low priority given to operation improvement — making new sales always seems to come first. A larger business, they reason, will have more resources for getting operations in better shape.

- No structure — they don’t stem from a rational approach (starting from a risk & opportunities analysis, broken down in actionable steps, documented so people know what they are responsible for, etc.)

That’s quite frustrating. Most of the middle managers still don’t get the fact that highly efficient and capable processes will get them better grades on customer audits, will make current customers happier, and will have a direct impact on sales.

Or, when they do get that fact, they are pretty cynical about the whole reasoning. It sounds too simplistic to them.

How to arrive at a good process improvement action plan?

Make good use of the 7 basic quality tools. That’s probably all you need! As Dr Ishikawa wrote:

From my past experience, as much as ninety-five percent of all problems within a company can be solved by means of these tools.

So, how to use these tools for driving quality improvement?

- Make a list of past issues (the “check sheet” tool, or any number of other ways of collecting data)

- Sort them by frequency (the “pareto chart” tool)

- Select the 1 most frequent issue

- Analyze it with the “cause-and-effect diagram”, break the process down with a flow chart, try to find patterns with the “histrogram” or the “scatter diagram”

- Select the 1 or 2 main causes of that issue, and drill down to the root cause(s)

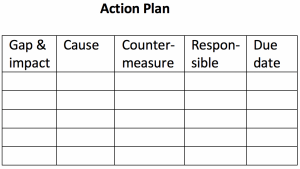

- Set up an action plan to address the main root causes: Action | Responsible person | Due date | Status

- Implement the actions, measure results, keep it in place if the issue comes up less often

- Go back to step 2, select the second most frequent issue, go over the process again

- Every time, make sure to document the changes and to find ways to make them permanent.

That’s the best way I know to fix issues, and to improve processes, in a relatively short amount of time.

Other approaches also make sense, depending on the goals.

If you want to reduce cycle times, you might want to do as follows:

- Draw a value stream map of the entire production, and include production of the main materials/components if possible

- Look at areas where much inventory builds up. Can you raise the capacity of the process immediately following those areas (they are probably bottlenecks.)

- Can you find ways to reduce changeover times in some processes? (For example, do you really need to stamp 10,000 pieces of the same part before changing to another part?)

- Can you “connect” two processes, so there is no need for a time & inventory buffer between them?

- Draw a “future state” map that can be implemented in the next 3-6 months

- Break down the tasks, and set an action plan: Action | Responsible person | Due date | Status

- Review the action plan regularly, make progress visible, keep pressure on

- Once you have implemented the whole plan, go back to map the system again, confirm lead times are markedly shorter, and start again at step 1

Same approach if the goal is variable cost reduction: build a model in Excel that replicates the cost structure, break it down and analyze it until you see the main cost drivers, etc.

As I wrote above, it takes a structured approach, involvement of the team that will have to do implementation, and (the hardest of all) continued focus and commitment over time.

What do you think?

No comments:

Post a Comment