Over the past 20 years, an entire industry has appeared in China to offer quality inspection services. It was a response to the lack of reliability of most suppliers, as well as their refusal to take responsibility for problems found after shipment.

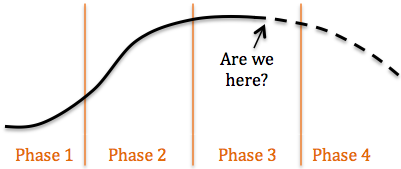

But I am wondering if the inspection market is still growing.

Long-term trend of the third-party QC inspection market

Phase 1:

Some large companies start buying directly. Quality control firms like Bureau Veritas or Intertek hire thousands of inspectors to cope with the demand from large retailers (and the importers who sell to these retailers).

Phase 2:

This trend gains speed. The growth of the inspection market is explosive, as more buyers find out that buying directly in China is pretty risky.

The market price goes down. For example, Asia Inspection offers a flat price below 300 USD for even the smallest clients, and is quickly imitated by tens of new entrants.

Phase 3:

In their rush to respond to demand, third-party QC firms seriously lack imagination. Some importers become frustrated with final inspections:

- When problems are discovered, it is too late; when no problem is found, it is useless,

- The only way to find problems earlier is to inspect during production, which means doubling the QC budget.

Hundreds of companies are essentially offering the same service. A handful (ProQC, InTouch) try to offer a better service than Bureau Veritas or Intertek. Many competitors are cheaper, and sometimes better, than Asia Inspection and SGS.

All this competition focuses attention on price. Some buyers accept a lower reliability, if they can slash their QC budget by 40%. They hire their own inspectors, or they work with cheap Chinese inspection companies.

The increased pricing pressure seems to indicate that the market has matured, and is about to decline. Maybe I am wrong, but the signals are here.

Phase 4:

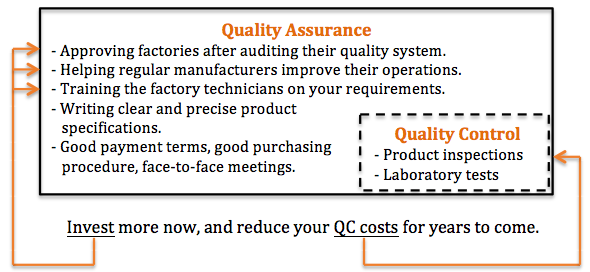

More and more purchasers decide that inspections are not the best response in all cases. They explore new options to reduce their QC budget — for example supplier self inspection.

For example, by adapting the quality control plan to each type of supplier, as I proposed here.

- For the good suppliers, skip-lot QC is enough,

- For the new or worst suppliers, it is essential to invest more attention at the beginning of the production cycle:

What do you think?

No comments:

Post a Comment